How does the F theta lens scan to reduce distortion?

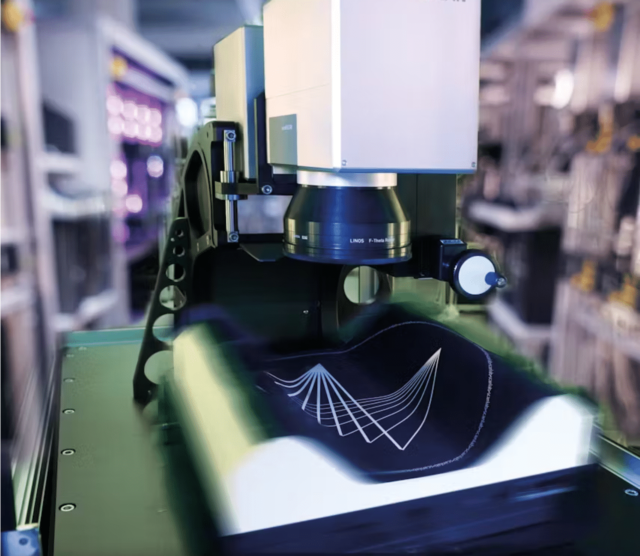

The F Theta lens works as a laser scanning system. It uses two-axis galvanometers to scan any object and act according to the angle on the image plane. By introducing an f-barrel distortion through the F Theta Optic while scanning the lens. It becomes a great option for a flat field. With this, you can laser scanning, marking, engraving, and cutting systems. By adding a specific amount of barrel distortion to a scanning lens, it becomes an excellent choice. These diffraction-limited lens systems can be customized to meet the needs of an application. They can take into account wavelength, focal length, and spot size. The distortion will not exceed 0.25% across the entire field of view.

Why Superior CCTV is the best at producing high-quality lenses?

Superior CCTV manufactures high-quality f-theta Lens systems for laser scanning and engraving systems. These F theta Optic systems are designed and manufactured to produce barrel distortion. It displaces the linear line and the angle of incidence (theta). Each Lens and scanner lens is an array of 3 to 4 air-spaced components mounted in a sturdy plastic housing. The Lens systems allow for compact scanning. It makes the work easy because it is not complicated and bulky.

Overview of the F Theta Lens

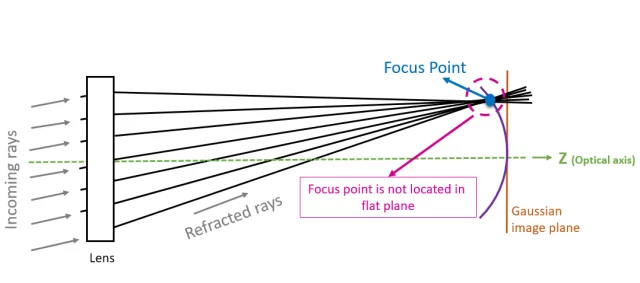

F-theta lenses are used for laser scanning systems that require a flat plane of images and high resolution. The image height of an F Theta is proportional to the scanning angle by introducing a certain amount of barrel distortion into the lens. These diffraction-limited lens systems can be designed to achieve the desired spot size with a distortion of less than 0.25 percent of the field of view. These lenses are the most useful lenses, as they always come in handy whenever the need for laser scanning comes to generate a flat image. They are preferred and known as the flat field objectives, and here are some points to look at:

Compact and easy design

F theta is a lens that can help the operator to lessen the optical components when needed. It also makes a flat image plane with the designed result.

High resolution

If you want to create some quality and error-free images, you can use the lenses for printing and scanning.

High intensity

Superior CCTV lenses can also develop high intensity for welding and engraving to provide the potential result.

Proportional Image Height

The lenses also come in different sizes and heights. You can produce image height proportion by just scanning angle and barrel distortion.

Low-field curvature

You may get the most useful lens from Superior CCTV for low-field curvature. You can even get the most out of it while using the lens to have a large image file.

Homogenous focus quality

Just in case you want to know how F Theta Optic can help and why it is good, well they produce focus and quality in the image field. They are even useful for many other works like drilling on printed circuits, microboards, and electronic parts.

What Are the F Theta Lens Characteristics?

When you select an f theta telephoto lens, make sure to follow the parameters such as wavelength, spot size, and scan field dimension. The scan length is known as the scan field diameter. It is also short-formed as SFD. The diagonal length is the area squared in the image plane where the laser is focused by f-theta lenses. The SFD determines your camera’s deflection and focal distance. OSA is the name for the angle between the normal output beam and the image plane. The angle does not remain constant throughout the image field. However, the OSA change is so small that it won’t affect scanning applications. The output scan angle remains at zero. The maximum OSA to avoid vignetting is the optical scan angle.

How Does F Theta Lens Focus on the Length and Scan the Size of an Object?

You can calculate the size of the system using the wavelength and focal length. The wavelength effectively enters the beam and then it divides the constant C. Laser scanning relies on the ability to place the spot in any location within the flat image plane. A F Theta Lens makes capturing a perfect picture possible. It spots a diameter chart and shows how one can work according to the field position. The distance between the paraxial focal point and the f-theta lens is known as the back working distance. The back focal distance, or BFL, is the distance between the paraxial focus and the apex (the outer glass element) of the lens. Our f-theta lens designs are designed at Superior CCTV to minimize field distortion and curvature and provide a flat plane of image. Our factory-standard lenses are designed to have maximum distortions of less than 0.25% and transmittances of more than 90%. Our lenses are made of high-quality silica, which has a high resistance to damage. The f-theta lenses have amazing focal lengths ranging from 63mm to 645mm. It also offers custom optical coatings for UV with great visibility and infrared use.

We provide f-theta optics that can optimize wavelengths of 355 nm (532 nm) and 1064 nm (1064 nm) as per the Industrial Standards.

The F-theta Lens design is compact with 3 to 4 elements.

It’s transmittance is >90%.

The distortion (max.) is <0.25%.

You can consider the size of the lens according to your work and choose the one that best fulfills your needs. The larger the focal length of F-theta optics, the larger the focusing spot and the wider the marking line would be.Focal length is available from 63mm to 635mm. Custom optical coating: working wavelengths range from UV to visible to infrared (10.6 μm—CO2; 1064 nm—fiber; 355 nm—UV). The entrance beam diameter of common machines is 12 mm. It is smaller in size and focal length. They give a great engraving effect. Choose the suitable thread for machine installation; the common mounting threads are M85, M55, and M35. F-theta Lens is customized to meet specific needs.

What is the Utilization of F-Theta Lenses and How Does It Help?

F Theta Lens is important in the arena of technology and the world of cameras. It offers great solutions to the challenges traditional lenses face while scanning applications. As laser technology becomes accessible and used in engraving material processing, you need professional support with consistency and focus. Traditionally, scanning systems require galvanometers that help the linear movement and enable diverse usages like engraving, drilling, and cutting. However, if you wish to use conventional lenses for your setup, it might be less helpful but provide you with some help. It’s a laser beam that remains deferred from the optical axis. On the other hand, the profile of the beam also remains unwarranted due to some changes. This is a phenomenon that remains rooted in the lenses while focusing on the curves. It makes a great contribution to the curvy and alteration optical power of the surface. The fluctuations create errors in the manufacturing procedure.

If you wish to avail of f-theta, you can avail of the lenses from Superior CCTV and use transformative solutions for better solving the challenges. With the help of f-theta lenses, you can transform every piece of information and image into a solution. You can even rewrite the narrative effortlessly with the help of laser systems. You can even focus on the laser beam to maintain a spot for the scanning field irrespective of the image’s deviation from the optical axis. It may even be helpful, as its characteristics can create a wonderful flat field. It not only moderates optical errors but also helps you enhance your image quality, accuracy, and uniformity with the help of laser processing.

F-theta lenses can be utilized in many different companies and industries:

Easy-Laser Scanning and Engraving

The lens and f-theta are important parts when it comes to laser scanning. It needs quality flat imaging for high resolution and work.

Materials Processing Step

The F Theta Lens can be used for welding, cutting synthetic materials, and drilling as well.

Image Transfer

F-theta lenses are absolutely helpful when it comes to image transfer systems.

Biotechnics

The F Theta Lens is used for confocal microscopy and ophthalmology.

Speedy Micro Drilling

The F Theta Lens is not a general product because they are even used in drilling and printing circuit boards.

Speedy Marking

The lens is even used in electronic parts for high speed. You must use the lens to produce a linear displacement with different defective angles. It also removes complex electronic problems and corrects the errors. Apart from these benefits, it also provides flat focusing on the surface and finds out the size while scanning. If you are looking for a top-rated CCTV Lens Provider Online or Offline, You should visit Superior CCTV for top-quality CCTV Camera Lenses.