The electric vehicle industry is experiencing rapid growth, as top brands are planning their own electric vehicle launches. As these EVs are environmentally friendly, they do not cause pollution while saving minerals and resources like petrol and diesel. The rise is causing immense pressure on manufacturers to produce high-capacity, safe lithium-ion batteries. While the production of batteries with such precision requires a SWIR fixed focal length lens. So, microscopic layer inspection of anodes, cathodes, and separators can be performed with precision and clarity. Battery inspections were traditionally done with a visual inspection, but this is no longer sufficient because it cannot see inside the bonded layers.

The rapid expansion of the EV industry is driven by strong support for electric vehicles, from resources to funding. Meanwhile, the government is also supporting and promoting the concept of electric vehicles. In this blog post, we will explore a non-destructive way to inspect the SWIR lens with a fixed focal length.

Advanced Transparency Support: How SWIR penetrates Battery Layers

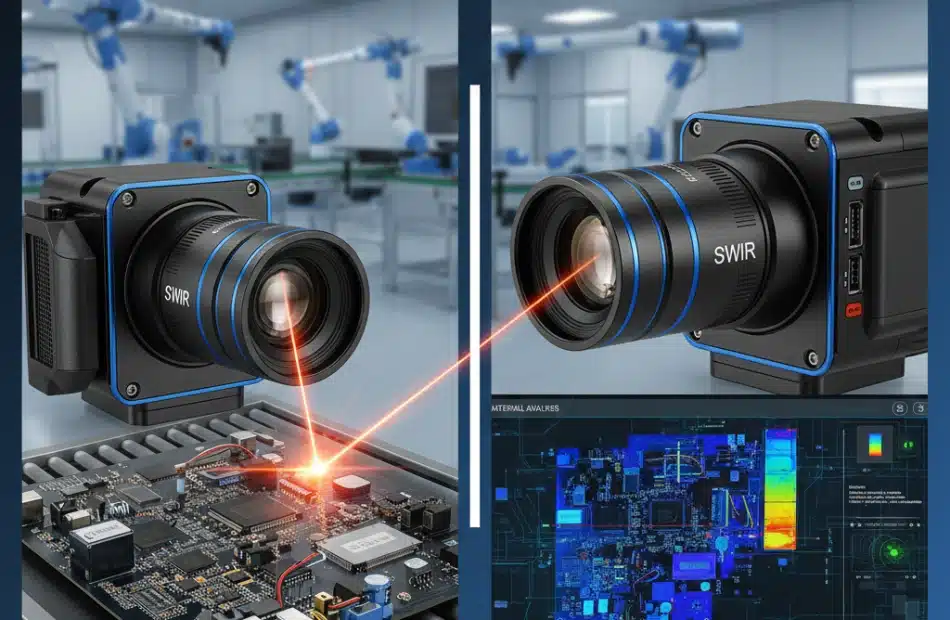

The speciality of the SWIR fixed focal length lens lies in the way it interacts with materials differently from visible light. In the manufacturing of lithium-ion batteries, inspection is a crucial step because verifying the internal structure after layer bonding is no longer possible. For the human eye and standard camera lenses, the separator film (a polymer separator film) becomes opaque and white. Thus, it becomes visually impossible to verify whether the electrodes underneath are perfectly aligned or if dangerous contaminants have slipped in during assembly. SWIR light generally operates in the 900-1700 nm range.

The fixed focal length lens did justice to the inspection process by verifying the internal bonding at this wavelength range. Making polymer-separate films transparent or semi-transparent allows the inspection system to look through the top layer. It verifies the alignment of the copper and aluminium foils beneath. Additionally, foreign particles, such as microscopic metal shards, appear dark and opaque against the transparent film. Capturing these images requires much more than just an SWIR sensor. They also require a perfect light spectrum and other features. Regular lenses, which are built for visible light, are not useful here, as they are designed to block infrared.

Which means they end up blocking the very signal you need while capturing an image. As a result, you get a dark, useless image. However, specialized industries have developed robust machine vision lens to deliver sharp, reliable visuals for demanding inspection tasks. Here’s a list of cameras present for high magnification at Superior CCTV.

Typical Specification of SWIR Fixed Focal Length Lens

While selecting optics for use or installation in an industrial application, verifying specific parameters is critical. For example, verifying spectral range and mechanical stability is paramount. Below are the typical technical specifications for the high-performance SWIR fixed focal length lens.

| Specification Parameter | Technical Detail | Why It Matters |

|---|---|---|

| Spectral Range | 800nm – 1700nm | Optimized for Short-Wave Infrared transmission; allows visibility through silicon, plastics, and organic dyes. |

| Focal Length Options | 8mm, 12mm, 16mm, 25mm, 35mm, 50mm | Fixed focal length lenses ensure consistent calibration and measurement accuracy compared to zoom lenses. |

| Max Image Format | 1-Inch (Ø 16mm) | Covers large-format SWIR sensors (such as InGaAs sensors) without vignetting (dark corners). |

| Mount Type | C-Mount | The industry standard for identifying a compatible machine vision lens ensures easy integration with existing industrial cameras. |

| Iris & Focus Operation | Manual with Lock Screws | Critical for high-vibration factory environments; “locking” the lens prevents focus shift during operation. |

| Optical Coating | SWIR-Specific AR Coating | Prevents ghosting and maximizes light transmission in the infrared spectrum, which standard lenses block. |

| Distortion | < -1.0% (TV Distortion) | accurate dimensional measurement; essential for inspecting battery tab alignment or wafer geometry. |

The Importance of Fixed Focal Lengths in Automation

Industrial automation makes workflows smoother, faster, and more efficient. Thus, adapting it with a fixed focal length in lenses will definitely result in significant changes across the entire sector. Here are a few points that highlight its importance in automation.

1. Consistency in Imaging

The automation with fixed-focal-length lenses helps deliver stable magnification and field of view, eliminating the common variability of zoom lenses.

2. Precision for Machine Vision

Here, it ensures accurate defect detection, robotic guidance, and quality control in automated workflows.

3. Speed & Efficiency

The high-speed environments are supported by reducing recalibration time and enabling faster decision-making.

4. Reduce Complexity

Automation with fixed-focal-length lenses simplifies design by requiring fewer moving parts. These result in lower mechanical failure risks and maintenance costs.

5. Repeatable Accuracy

Automation makes repetitive tasks easier, like assembly line inspections or pick-and-place operations.

6. Cost-Effective Reliability

It provides long-term stability and performance without expensive adjustments or replacements.

7. Workflow Optimization

Enhances the automation systems by ensuring smooth, uninterrupted operation across demanding industrial settings.

Final Thoughts!

As electric vehicles evolve, their batteries will become denser and more complex, requiring even stricter inspection standards. However, adopting a SWIR fixed focal length lens technology can help manufacturers in reducing waste and even help in dangerous recalls. Get in the groove and make a change in your monitoring, whether you are inspecting solar panels or EV batteries. Upgrading to a high-quality SWIR lens is the most effective way to see beyond the limits of normal vision and ensure product safety. If you’re looking for a reliable, trusted manufacturer of such lenses, look no further than Superior CCTV.

Whether you are an engineer, a production manager, or a researcher in a field that requires the use of a machine vision lens. Don’t wait, and explore our product catalog today to get the desired lenses. We are a trusted manufacturer with years of market presence and high-quality lenses that suits every needs of individuals.

FAQs

How fast will my order ship?

We understand the tight deadlines installers face and ensure the fastest possible delivery. Most of our orders placed before our daily cutoff time are shipped from our warehouse on the same business day. We also offer various shipping methods, including ground and expedited air options, to ensure the client’s equipment is delivered on time. Without delay, exactly when they need it for the job.

Can your team help me choose the right cameras for my project?

Yes, our expert team is always ready to assist with the product selection. If you can describe your project needs, such as the distance you need to view or the lighting conditions. Our team will recommend the perfect mix of fixed focal length lens and camera models to ensure you get the best coverage within your budget range.

What are the Superior CCTV warranty policies for lenses?

We stand behind the quality of our products. Most of the Superior CCTV equipment comes with a comprehensive manufacturer’s warranty to protect against defects in materials and workmanship. To know about the product warranty, please check the specific product age. The exact warranty duration is mentioned or you can contact our team for details on our hassle-free RMA (Return Merchandise Authorization) process.